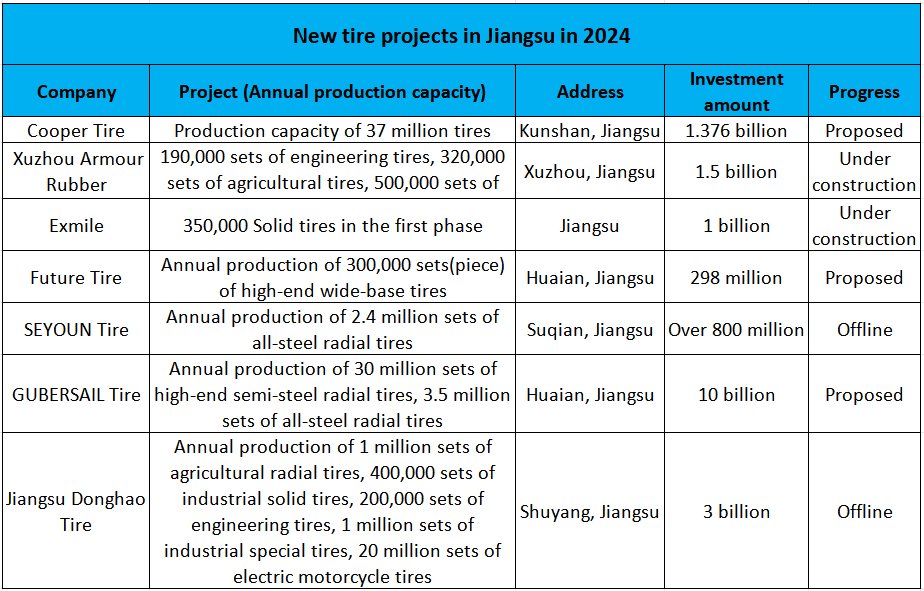

In 2024, while the overall development of the tire industry in Shandong Province has slowed down, the tire industry in Jiangsu Province has ushered in an explosion in production capacity.

According to incomplete statistics, seven major tire projects will be put into production or planned to be built in 2024 alone, with a total investment of nearly 20 billion yuan. We have sorted out the specific progress of the project and found that Jiangsu is becoming a hot spot for domestic tire investment.

GUBERSAIL Tire's 10 billion project is in the works

The GUBERSAIL Tire Project is a major project in Jiangsu Province with a total investment of 10 billion yuan. After completion, it will be able to produce 30 million sets of high-end semi-steel radial tires and 3.5 million sets of full-steel radial tires annually.

On June 6, Shi Zhijun, Secretary of the Huaian Municipal Party Committee of Jiangsu Province, visited Huaian District to investigate and promote the construction of major projects and went to inspect the GUBERSAIL Tire Project.

According to the information, the first phase of the GUBERSAIL Tire project is expected to take 18 months to produce 15 million sets of high-end semi-steel radial tires, and build a rubber mixing workshop to a finished product storage area. The second phase of the project will produce 15 million sets of high-end semi-steel radial tires and 3.5 million sets of full-steel radial tires, and both production capacity and market share are expected to increase significantly.

Donghao Tire accelerates production expansion

Donghao New Material was established in April 2021 and plans to invest 3 billion yuan to build a tire production and sales project based on the tire production technology of Jiangsu Donghao Rubber The new Qixiong plant of Donghao Tire covers an area of approximately 334.89 acres and has a construction area of approximately 177,600 square meters.

The project is divided into two phases. Currently, the first phase of the solid tire project has been completed and put into production. The annual production capacity can reach 200,000 sets of agricultural radial tires, 500,000 sets of engineering machinery tires, and 1.8 million sets of industrial special vehicle tires. The project is expected to be completed in 2024 with a total investment of up to 3 billion yuan.

On October 18, 2023, the solid tire project of Jiangsu Donghao New Material was successfully put into trial production, and the first solid tire rolled off the production line.

On June 18 this year, the groundbreaking ceremony for warehouses 2#, 3# and 4# of Donghao New Material was grandly held, and a number of leaders attended the ceremony.

SEYOUN Tire's strength increased

On April 15, the first product roll-off ceremony of the "Ji Shi" tire was held at the Jiangsu Suqian SEYOUN Tire's smart factory with an annual production capacity of 2.4 million sets of all-steel radial tires.

The second phase of the Jiangsu SEYOUN Tire project started construction at the beginning of this year and is expected to be completed and put into production by the end of this year. After production starts, the annual production capacity of SEYOUN Tire's all-steel radial tires will reach 3 million, which can add an additional output value of 3 billion yuan.

It is understood that Jiangsu SEYOUN Tire originally mainly produced bicycle, electric vehicle and motorcycle tires. In 2023, it announced its entry into the all-steel tire manufacturing field, and its total sales output value in 2023 reached 1 billion yuan.

In addition, the Kunshan Cooper Tire, Xuzhou Armour Rubber and Exmile Tire projects have all started construction. In fact, the tire industry in Jiangsu Province is already very strong, including Jiangsu GS Wuxi Factory, Hankook Huaian Factory, Double Coin Rugao Factory, Kumho Nanjing Factory, Armour Rubber, Cooper Kunshan Factory, Maxxis Kunshan Factory and many other tire companies.

In the upstream raw material industry, Jiangsu Xingda Steel Tyre Cord and Zhongtian Steel Cord are among the best in the country. With the implementation of new projects one after another, Jiangsu's tire industry, with its unique scale advantage, is developing into the second largest industrial cluster in China after Shandong.

DLFTECH is a professional equipment marketing & service company built by a senior R&D and marketing team in the tire & conveyor belt equipment industry. Benefiting from the rapid follow up of the international rubber industry's process re-engineering and the demand for industrial intelligence, DLFTECH, the best of the best, has rapidly developed into a new star in the international rubber machinery industry.

If any tire or conveyor belt industry customers need such as track shaping & curing press, tire mold online intelligent laser cleaning system, silent sponge sticking equipment etc., please feel free to contact info@delphygroup.com.